Technology for the control and monitoring of the cold chain

By Emerson

In today's world, supplying the population with basic needs such as medicines and food is closely linked to food safety and a network of procedures that seek to maintain quality under health requirements.

It is here where we find terms such as the "cold chain" which, although they have different definitions, can simply be understood as the set of successive stages in production, processing, logistics and marketing where low temperatures must be maintained to maintain quality and keep food or heat-labile medicines to avoid losses or a decrease in the quality of the products in question.

To improve the way we control and monitor the cold chain, various technologies have been developed and others have evolved to be more efficient through the use of equipment and devices that are practical in use and at the same time environmentally friendly.

In this scenario, the American company Emerson delivers key solutions for all industries.

In the food sector, according to the study "Global food losses and food waste" it is estimated that of the total food destined for human consumption at a global level, a third part becomes loss or waste.

This is not to mention the other large portion that corresponds to foods that lose added value or suffer from a decrease in quality due to poor handling at some point in the supply chain. We must not forget at the incorrect handling of the processes involved in the cold chain increases the potential risk of the proliferation of microorganisms dangerous to human health in the case of food and the loss of effectiveness in the case of medicines.

These aforementioned data have motivated the development of new technologies that can be applied at some point in the cold chain or on the route known as "from field to table".

The ability to monitor and control the cold chain offers the opportunity to reduce waste, avoid losses or prevent quality decline through timely corrective action when one of the critical variables in the cold chain is compromised in the process.

New technologies

New technologies for the control and monitoring of the cold chain are also being developed to operate with the least possible impact on the environment. For example, we find equipment for refrigeration systems that are manufactured for natural refrigerants such as ammonia or carbon dioxide. These systems allow the removal of field heat to start the cold chain process or to cool large process areas. Once the cold chain has started, companies like Emerson manufacture products that allow the monitoring of loads in real-time, where data on location, temperature, humidity or other variables such as carbon dioxide levels or door opening can be obtained.

Programs such as the GO GreenSense initiative have been implemented for these devices, which enables the responsible disposal of disposable devices through a reward scheme for promoting recycling.

According to the company, there is a great variety of variables in addition to the temperature for which it is also convenient to keep a record that can be in real-time to take preventative or corrective actions at the moment, thus solving the fact that said variable is outside the established ranges for quality control.

Among the most useful devices for monitoring low-temperature transport conditions, the following can be found:

- Destination reading equipment, also known in the industry as "loggers", allows you to keep a digital record of temperature and humidity, from where the information is downloaded for later analysis. These devices make it possible to measure the temperature and humidity of the environment or surrounding environment, and if applicable, they also record the internal temperature of the product through test tubes or probes.

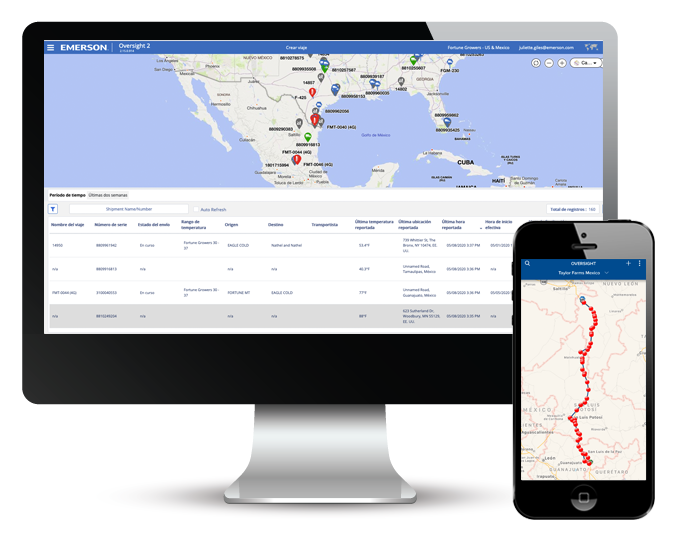

- Real-time reading equipment, also known as "trackers" or "thermographicators", allows the visualization of each of the variables through platforms that can be web pages or mobile applications. These platforms carry out alerts when any of the variables fall outside its control range, allowing corrective actions to be taken. The real-time devices are installed in the mobile units to monitor the journey ensuring the temperature, the percentage of relative humidity and the location in real-time. They also make it possible to detect the opening of doors through brightness sensors that allow the user to know each time the transport has been opened. In addition to these devices, you can find some other more specific ones, for example, those used to measure CO2 levels that allow the control of the ripening of fruits when they are transported, or where appropriate, the monitoring of control atmospheres to ensure the optimal levels in the composition of the surrounding air.

The equipment in real-time has been very successful in the market and is being a great ally in monitoring the cold chain due to the direct benefits it provides. For example: sending an alert in real-time if the maximum temperature is exceeded, allows the operator of the refrigerated unit to be contacted to validate that the refrigeration is working properly.

Another useful feature works in case of theft or to try to locate transportation. The devices have an option to report before official reports of theft or loss. This feature has enabled many producers to retrieve freight transports after loss or theft, or when the unit has simply gone off course.

In addition to evolving to different markets and industries, the products for monitoring the cold chain are constantly changing and evolving, migrating to new technologies, such as improvements in location.

Currently, a large number of devices are being manufactured to operate where there are 4G/5G cellular networks since some countries no longer have or will no longer have the 2G cellular network, for example, Japan, Canada, Taiwan, Singapore, South Korea, Australia, etc.

At the same time, the new equipment has also been developed with batteries that don't use lithium, allowing a greater range of compatibility and expanding its use to other means of transport.

Emerson is committed to the development and innovation of solutions for the market either through the reading equipment at the destination “loggers” or through the real-time reading devices “GO Real-Time” to monitor land shipments, air or sea with different cellular technology for a precise location.

For more information, contact Rodrigo Valenzuela from Emerson Chile at rodrigo.valenzuela@emerson.com; Adrian Campos from Emerson Costa Rica at adrian.campos@emerson.com; or Adolfo Santos from Emerson Mexico at adolfo.santos@emerson.com.